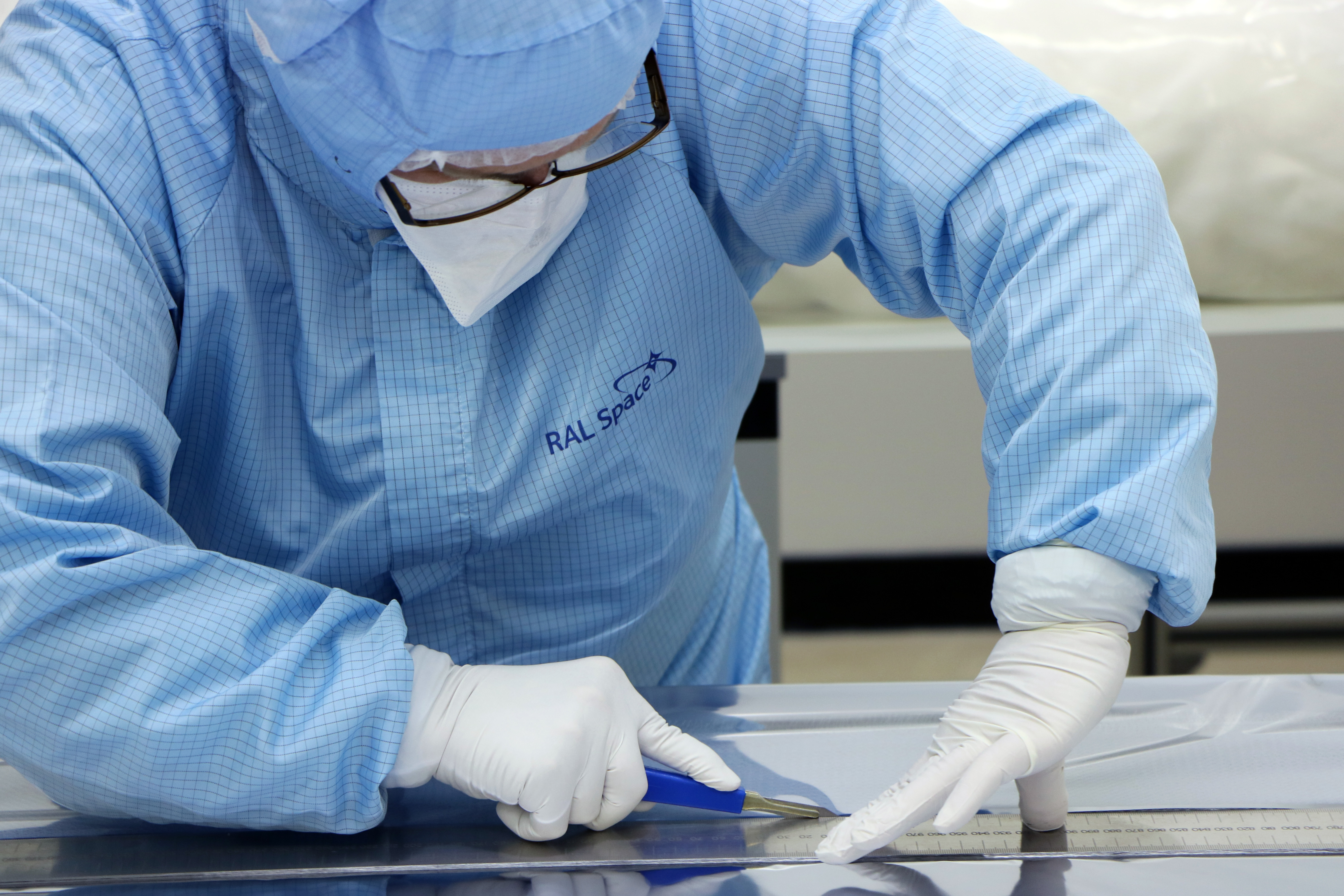

Making thermal

blankets is a very skilled practical task; technicians need to be able

to precisely measure, cut and in some cases, sew the blankets. This

requires nimble-fingers and the skill to think three dimensionally. Many

of these skills are used by crafts people, so the job advert called for

people with a love of sewing and crafting.

Angela Ashill was

looking for a change of career and happened to see an advert for a

skilled craftsperson at RAL Space. Although the job was nothing like

she'd ever done before, she knew she had to apply.

“I never

expected to work anywhere like this" Angela said, “I had been running a

card-making business at home when I saw the advert for the MLI position

at RAL Space. I was intrigued – at the very least I thought it would be

interesting to go to the interview. But my craft business and my

previous career as a radiographer gave me the confidence to apply."

Claire

Morgan, like many mums, struggled to balance working against the costs

of childcare after the birth of her third child. She became an OFSTED

registered childminder and learned to sew and bake for family and

friends.

“After my kids went to school I started thinking

about doing something else but it needed to fit round them. A friend of

mine who already worked for RAL Space in engineering showed me the job

advert. She suggested I give it a go."

The

third new team member, Kim Morgan, has always had an interest in sewing

and science – but never imagined she would be sewing thermal blankets

in a laboratory.

The

third new team member, Kim Morgan, has always had an interest in sewing

and science – but never imagined she would be sewing thermal blankets

in a laboratory.

“When I saw the job advert on the RAL Space

website it looked like my ideal job because it involved making stuff"

said Kim. “The interview seemed very technical but when they took us

down to the cleanroom and made a piece of blanket I thought, if this is

what the job is about, it's what I want to do."

While RAL Space

has had a growing number of customers for MLI expertise, recruiting the

right staff to keep up with demand had been an ongoing issue until

Angela, Claire and Kim joined Steven Cross in the team.

“We

realised we had been coming at the recruitment process as engineers;"

said Edward Jones, MLI Facility manager. He explained, “the issue was

that we were thinking about the skills we had, rather than those

actually needed for the role. So the recruitment team re-phrased the

advert, took out much of the technical jargon and refocused on the craft

skills needed for the job"

It's clear that the MLI team have quickly got to grips with the technical nature of the job and take pride in their work.

“We

get given a pattern from the engineers and what they want to achieve,"

explained Angela, “We need to work out the stages of putting everything

together. There really isn't as much sewing as I had thought, much more

cutting the pattern and sticking with special tape."

%20at%20work%20in%20the%20MLI%20Facility.JPG) With

every kilogram launched into space costing several thousand pounds,

everything has to be very precise and everything has to work perfectly

when it gets into orbit.

With

every kilogram launched into space costing several thousand pounds,

everything has to be very precise and everything has to work perfectly

when it gets into orbit.

Claire described the process of keeping

everything clean and correct, “We weigh everything and cut accurately to

make sure we don't add excess weight. There can't be any stray fibres

or bubbles in the tape because the trapped air would expand and it would

come apart when the spacecraft is in a vacuum."

Kim agreed with

the need for care and attention “Each blanket is unique so you can't

rush it. If you rush it you'll make mistakes. I'm a very visual person, I

like to see something being made from start to finish. It is definitely

inspiring that they go into space."

And there are even some

skills that transfer the other way according to Claire, 'Working in a

cleanroom, with lots of visitors coming through RAL Space, I've become a

lot cleaner and tidier with my work at home and much more precise

making decorations for cakes."

RAL Space is just getting busier

with around 500 blankets to make for external projects over the next 2

to 3 years and growing interest from beyond the space sector.

Edward

said: “We are delighted with Kim, Claire and Angela, they had just the

skills we needed and are a brilliant addition to our team. With new

skills that wouldn't be available otherwise and a different way of

looking at the task. We need more people like this taking up jobs in the

UK space industry."

Search and apply for STFC RAL Space careers.

For more information please contact, RAL Space Enquiries

Image:

Image 1 - Technician cutting MLI precicely by hand. Credit: STFC RAL Space

Image 2 - Technicans rolling out layers of insulation to make MLI. Credit: STFC RAL Space