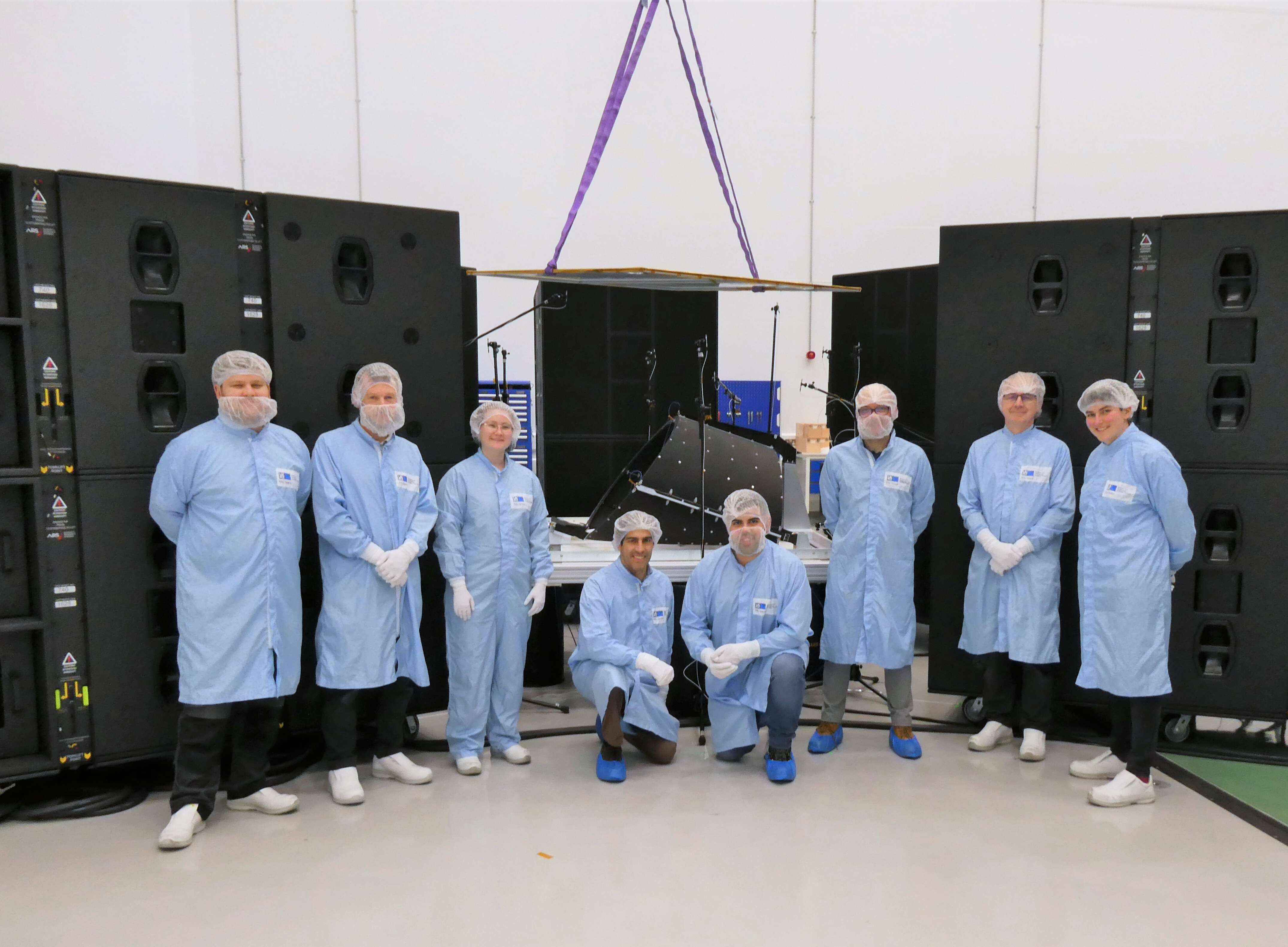

Teams from RAL Space, Active Space Technologies and the European Space Agency setting up acoustic tests in the NSTF. Credit: STFC RAL Space

Operated by RAL Space, the National Satellite Test Facility (NSTF) was established to ensure that spacecraft up to 7 tonnes can withstand the harsh conditions of launch and space. Officially opening its doors to customers in May 2024, the facility features range of state-of-the-art testing capabilities for large-scale spacecraft. This includes dedicated areas where mini-bus sized satellites are shaken violently to simulate rocket launch conditions, and “baked" in the UK's largest space test chamber to assess their resilience to the extreme temperatures they will face in Earth's orbit and beyond.

While many of the NSTF's capabilities build on RAL Space's existing expertise in space testing, acoustic tests are a new frontier – both for the organisation and for the UK.

As well as two large shaker tables, the NSTF's Dynamics Suite is home to 48 large speakers and amplifiers which can be configured to simulate the incredibly loud acoustic environment typical of a rocket launch. This testing, known as direct field acoustic noise (DFAN) testing, is vital to ensure the structural integrity of space components. This is particularly important for large, lightweight components as well as full structures, which can be susceptible to damage from acoustic vibrations during launch.

The NSTF team has successfully completed its first DFAN tests on components for the Ariel space telescope – a European Space Agency (ESA)-led project in which the UK is already playing an important role. Ariel will study the chemistry of around 1000 planets outside our solar system, with RAL Space leading the mission's international payload consortium, and University College London leading the mission science. These roles are funded and supported by over £30m of funding from the UK Space Agency.

“The successful completion of these DFAN tests is a crucial milestone, not just for RAL Space but for the wider UK sector", says Dr Ian Horsfall, Dynamics Group Leader at RAL Space. “Our team has done outstanding work extending our capability to test spacecraft components under these conditions that are as close to reality as possible. This achievement is a significant step forward for the NSTF and will benefit many future missions."

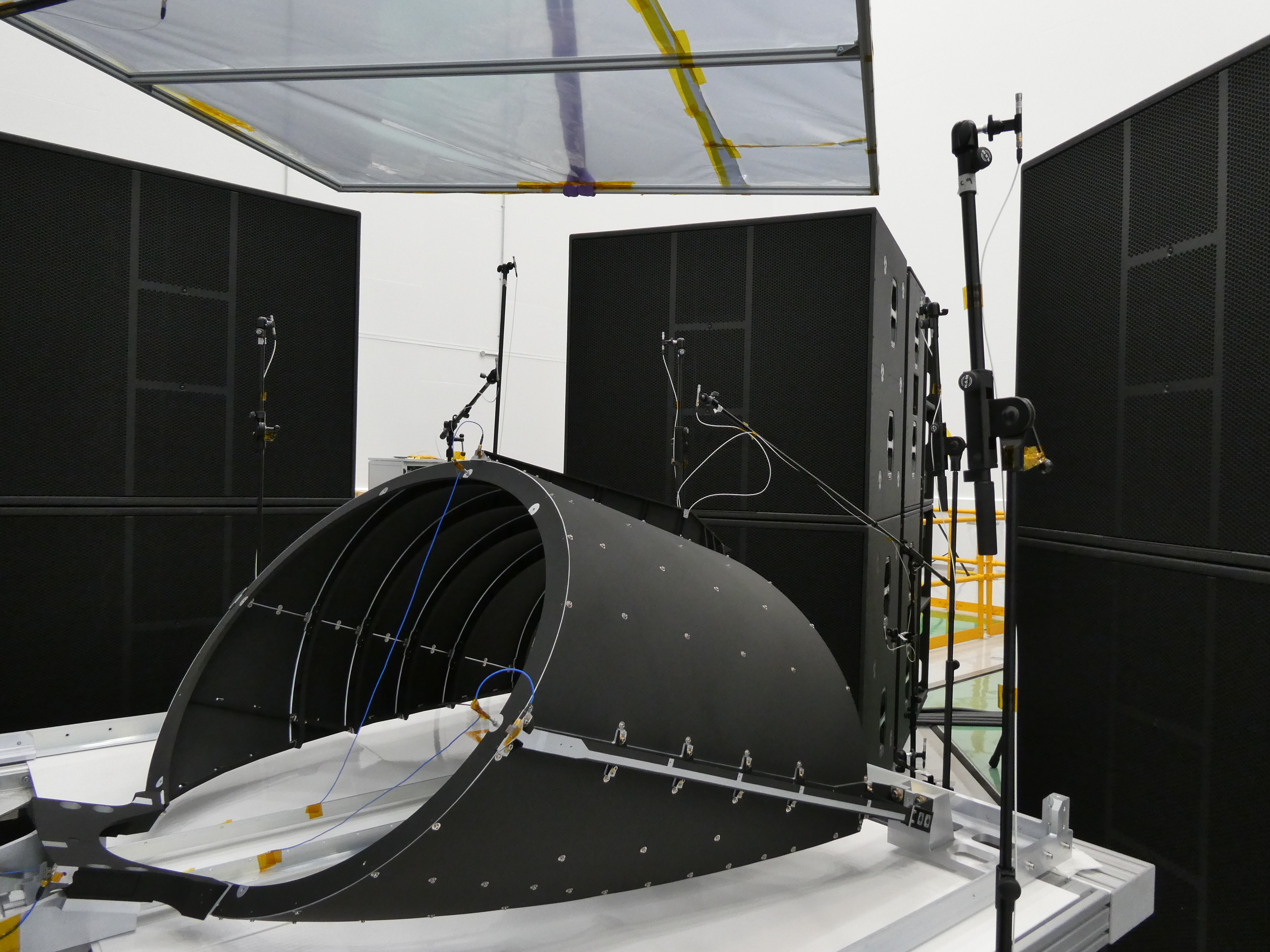

The Ariel baffle's engineering qualification model set up for DFAN tests. Credit: STFC RAL Space

The component undergoing DFAN testing was the telescope baffle's engineering qualification model (EQM), built by Active Space Technologies (Portugal). While this particular model won't fly on the final spacecraft, it serves as an essential step in validating the design and construction before the final flight model is assembled. After these acoustic tests, the baffle EQM will undergo further testing in RAL Space's thermal vacuum test facilities to ensure it can withstand the extreme conditions of space.

“The Ariel Payload Team at RAL Space were very excited to participate and observe this test", says Dr Rachel Drummond, Ariel UK National Project Manager at RAL Space. “Not only does it offer valuable lessons for testing the full Ariel payload's structural model later in the year, but it's fantastic to see the various components coming together from our partners across Europe."

Artist's impression of the Ariel telescope in space, with the baffle visible on top of the spacecraft. Credit: ESA